Sep 26, 2025

Theory of Constraints: simple steps to find your business bottlenecks

Hannah

Your business may be hitting an invisible wall despite your best efforts. The Theory of Constraints (TOC) reveals that every system has one core bottleneck that determines overall performance. By identifying and addressing this constraint, you can unlock growth, boost capacity, shorten lead times, and increase profits. Whether the limitation lies in policies, markets, or resources, TOC provides a systematic way to turn obstacles into opportunities for improvement. To make the process clear and actionable, you can use Xmind to map out constraints, track progress, and visualize solutions effectively.

How to spot bottlenecks in your business

Your business needs to spot bottlenecks before they choke operations. This is vital to keep things running smoothly. Tools like Xmind help you visualize these constraints and see how they affect your entire organization.

Common signs of a constraint

Your operations will show specific symptoms when bottlenecks exist. Here are the warning signs to watch:

Long wait times. Materials or information get stuck between process steps

Backlogged work. Work piles up at one process end while the other stays empty

High stress levels among team members in specific departments

Accumulating inventory before certain workstations

Alternating flooding and stopping of downstream workstations

One manufacturer found that work piling up before a specific machine or department points to a constraint. Your billing process might have issues if the finance team sees customers paying late and causing cash flow problems.

Types of constraints: policy, market, resource

Policy constraints come from internal rules that limit throughput. Break rules, minimum production requirements, and overtime limits fall into this category. To name just one example, see how a rule requiring full storage bins before moving to the next workstation creates alternating floods and stops at later stations.

Market constraints show up in supply or demand. Cost limits, competitor moves, labor shortages, or low product demand create these issues. Many apparent market constraints turn out to be internal capacity problems that stop you from meeting available demand.

Resource constraints include physical items (equipment, materials), knowledge (skills, expertise), or workforce issues (talent shortages). Physical constraints stand out easily. Knowledge constraints often go unnoticed yet substantially affect performance.

Real-life theory of constraints examples

Boeing ran into a bottleneck with their 737 production line. A time-sensitive wiring installation process slowed everything down. They redesigned this process to improve workflow.

Mazda's business turned around thanks to the theory of constraints. They learned their biggest problem was slow product development.

Dr. Reddy's pharmaceutical company found issues in their production policies. They pooled production capacity across products. This approach aimed to reduce stockouts but led to higher costs and inventory levels.

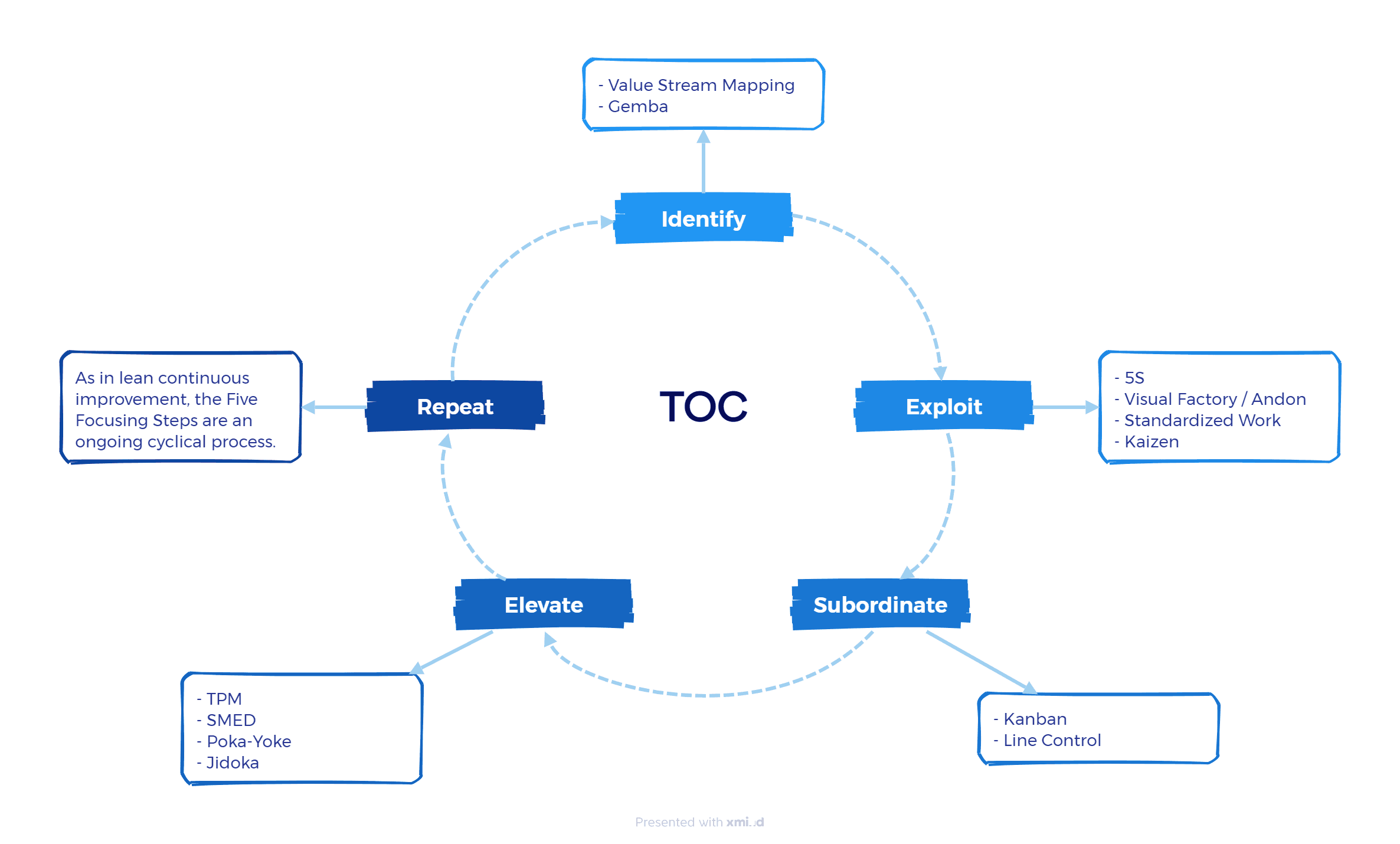

Simple steps to apply the Theory of Constraints

You've spotted your business bottlenecks. Now it's time to take action. The theory of constraints gives you a simple five-step framework to eliminate these productivity roadblocks.

1. Identify the constraint

Your first task is to find the exact bottleneck that limits your system's performance. This bottleneck acts as your weakest link - the constraint that controls your entire productivity chain. Watch for places with big work piles, constant rush jobs, or where your team feels stressed. Most managers don't deal very well with this step because they worry about future constraints instead of current ones. Note that fixing a constraint that hasn't shown up yet wastes resources. Your focus should be on finding your active constraint - the one that limits your throughput right now.

2. Exploit what you already have

Make the most of your current resources before buying new ones. Your goal is to push the constraint to 100% capacity with what you have now. The constraint should never sit idle - it needs to run non-stop without unnecessary delays. Most organizations find their constraints run at less than 50% capacity around the clock. You can often unlock 30% more capacity in just a few months at zero cost by streamlining your current setup.

3. Subordinate other processes

The next step is to line up all other activities to support the constraint. Your non-constraint resources might need to work less efficiently to make the whole system work better - it sounds odd but it's crucial. To name just one example, see how developers might need to help with QA tasks when they work faster than the QA team. Keep enough buffer inventory before the constraint so it never runs dry.

4. Raise with new resources

New investments should come only after you've squeezed every drop from your current setup. This might mean hiring people, buying equipment, or rolling out new systems. But don't rush to throw money at the problem—many companies skip straight to this step and miss the chance to use free capacity.

5. Repeat to find the next bottleneck

Breaking one constraint means another will pop up somewhere else. Go back to step one and start over. This creates a cycle of constant improvement that keeps your processes moving forward and propels development in your theory of constraints project management approach.

Mapping constraints visually with Xmind

When you map constraints visually, abstract bottlenecks become concrete and actionable. Xmind helps you frame complex challenges, connect steps of the Theory of Constraints (TOC), and design strategies that teams can clearly understand and follow.

Why visual thinking helps

Text alone often makes processes look messy and hard to follow. A visual map lays out nodes, connections, and dependencies in a way that mirrors how teams think. With Xmind’s different structures—like tree diagrams, logic charts, or timelines—you can reveal how decisions and processes interlink around a bottleneck.

For example, a supply chain manager can quickly sketch a radial map of their distribution flow and immediately highlight the warehouse as the limiting step. Finance, logistics, and operations all see the same picture, and discussion becomes more focused.

Xmind also strengthens retention: because maps blend words, structure, and symbols, your team processes them faster and remembers them better.

Building a constraint map in Xmind

Central node first: start with your main constraint, e.g. “Code Review Bottleneck.”

Five TOC steps as branches: Identify, Exploit, Subordinate, Elevate, and Repeat. Each branch can expand into subtopics with actions like “Automate lint checks” or “Add reviewer rotation.”

Relationships: draw arrows to show how an action affects the constraint. For example, link “Automate lint checks” to “Reduce review time.”

Colors and markers: use red to flag the active bottleneck, green for solved ones, and markers like priority icons or progress bars to show urgency.

Notes & attachments: add cost estimates, timelines, or relevant documents to nodes so decisions are supported by data.

Teams in manufacturing often build these maps to compare setup time reduction options. A product team might map software deployment steps and tag the constraint with a “High Priority” marker.

Using Xmind for team collaboration

Xmind enables real-time co-editing, so multiple teammates can refine the same map simultaneously. Everyone sees updates live, and comments stick directly to nodes for context-specific feedback.

Example: during a virtual workshop, engineers propose actions, product managers add constraints from user feedback, and leadership inserts policy considerations—all in one shared map. Permissions are customizable: share view-only maps for wider audiences or editing access for your core project team.

In distributed teams, this eliminates version chaos and email chains. The map becomes a living reference that keeps evolving as constraints shift.

Tracking progress with visual workflows

Once your constraint map is built, it doubles as a workflow tracker:

Add checkboxes and task info to nodes so progress is visible.

Switch layouts to a timeline view when you need sequencing, or an org chart when responsibilities must be clear.

Use version history to revisit past states if you need to analyze how bottlenecks evolved.

Export to PDF, PNG, PPT, or Markdown for reports, or share a secure link for stakeholders to review live.

A logistics team, for instance, might start with a map showing “Shipping Delays” as the constraint. Over months, completed actions get checked off, and the map shows a clear trail of improvements. When a new constraint emerges, it becomes the new central focus, continuing the TOC cycle.

Ready to visualize your constraints?

Use Xmind to map bottlenecks, align your team, and track improvements. Your next breakthrough could be just one constraint away.

Ready to visualize your constraints? Try Xmind today.

Integrating TOC with project management and lean

TOC's benefits go beyond using it alone. Xmind helps you map out integrated approaches to see how different methods can work together to lift your business results.

Theory of constraints project management use cases

Critical Chain Project Management (CCPM) extends TOC and reshapes the scene of project management. This method helps teams deliver projects on time and within budget by solving issues with resource availability and task dependencies. Project managers who use TOC see problems earlier, allocate resources better, and gain clearer visibility. TOC helps construction teams handle complex dependencies while making the best use of resources. Software development teams use it to spot bottlenecks in their development cycles, testing processes, and deployment pipelines.

How TOC complements Lean and Six Sigma

TOC and Lean work well together despite their different approaches. Lean aims to cut waste and costs, while TOC focuses on improving throughput by managing constraints. These differences make them perfect partners—TOC shows where to focus Lean activities. Six Sigma's analytical methods add to TOC by offering statistical tools that measure and analyze how processes perform. These methods combine to create TLS (Theory of Constraints, Lean, Six Sigma)—a detailed framework that handles constraints, removes waste, cuts defects, and makes everything work better.

When to use TOC vs. other methods

TOC works best to find your system's most important limiting factor. Lean shines when you need to reduce waste in your processes. Six Sigma fits best when you want to reduce variation and boost quality. Notwithstanding that, mixing these methods often gives the best results. TOC helps decide what to improve first, while Lean and Six Sigma provide tools to make those improvements happen. TOC gives clear direction for ongoing processes that affect business heavily or when goals are missed. Simple approaches might be enough for quick fixes or minor adjustments.

Conclusion

The Theory of Constraints helps you break through invisible barriers and uncover hidden capacity—often up to 30% more by using existing resources. Bottlenecks aren’t setbacks; they highlight your next opportunity to improve. Combined with methods like Lean and Six Sigma, TOC becomes a powerful driver of growth and efficiency. Use Xmind to map your processes, visualize constraints, and guide your team toward continuous improvement. Your next breakthrough could be just one constraint away.

FAQs

Q1. What exactly is a bottleneck in the Theory of Constraints?

A bottleneck is the most significant limiting factor in a system that restricts overall output or performance. It's the constraint that, when addressed, can lead to substantial improvements in system efficiency.

Q2. How does the Theory of Constraints approach bottlenecks?

The Theory of Constraints focuses on identifying the primary constraint (bottleneck) in a system and systematically improving it. This approach aims to increase overall throughput by managing and optimizing the most critical limiting factor.

Q3. Why is managing the bottleneck crucial in the Theory of Constraints?

Managing the bottleneck is essential because it determines the entire system's throughput. By focusing on improving the bottleneck, you can achieve significant gains in overall performance without wasting resources on non-constraint areas.

Q4. What are the main types of constraints businesses might encounter?

Businesses typically face three main types of constraints: policy constraints (internal rules limiting throughput), market constraints (supply or demand limitations), and resource constraints (physical, knowledge-based, or workforce-related limitations).

Q5. How can visual mapping tools help in applying the Theory of Constraints?

Visual mapping tools, such as mind mapping software, can help businesses clearly identify and visualize bottlenecks, track progress in addressing constraints, and improve team communication. These tools make abstract processes more tangible and easier to analyze and improve.